“The public image of hydrogen as an energy source is still heavily distorted,” explains Peter Stadthalter, a graduate engineer, managing partner of PS-HyTech GmbH. “In many conversations with potential customers, we experience that the German term ‘fuel cell’ suggests that there is combustion here and that drive energy is released directly. Of course that’s not true. A hydrogen system is more of an autonomous energy generator that works with simple and harmless chemical reactions and can be a smarter, more reliable, safer and cheaper battery replacement for smaller aircraft. “

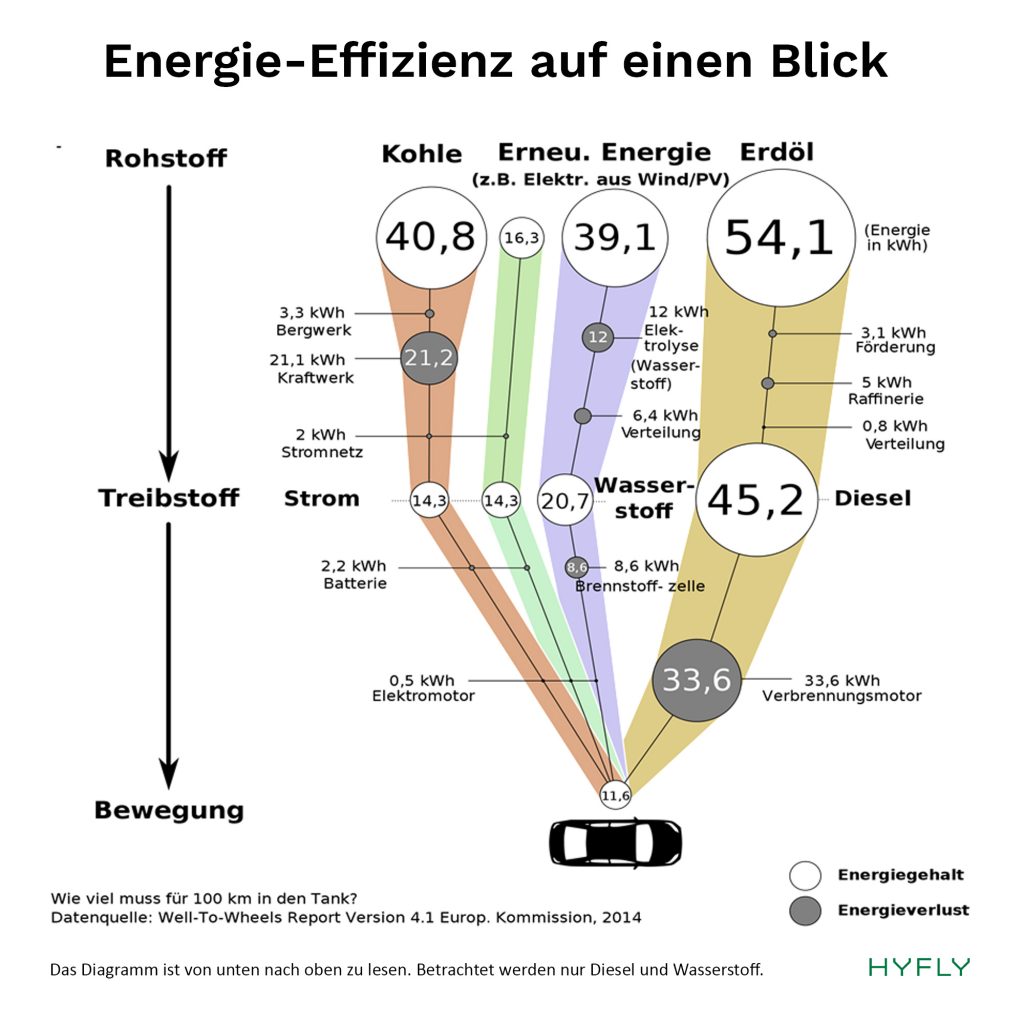

Hydrogen is a green energy storage medium that has been used in a variety of ways for over 100 years and can be generated directly from sustainable hydropower, wind energy or solar power in a very environmentally friendly way, with relatively little effort and without environmental pollution. Green hydrogen tops the overall energy balance of fossil fuels and coal. Basically, it requires distilled water, an electrolyte and electricity – there are more than enough of all of these worldwide. With a good electrolyser, a very high efficiency of over 70% can be achieved in the production of hydrogen. There is only one type of hydrogen, the energy content is always the same at 33 kWh per kilogram. There are differences in the type of storage or storage. The hydrogen can be chemically or physically bound in special carrier materials. Alternatively, it can be cooled down and liquefied or stored under high pressure.

Easier is further

“For use in small aircraft, we want to consciously avoid the cooling down and thus the liquid storage of hydrogen and have invented a new, extremely robust round tank shape,” explains Peter Stadthalter. “In this very light tank, we store hydrogen gas at a pressure of up to 700 bar. Our goal for the next two years is now to reduce the weight of the fuel cell system and the control technology by 90% and to save at least 80 kg in weight compared to an electric drive system with pure battery storage! “

In addition to the glide ratio, the weight of an aircraft significantly influences the engine power required to stay in the air and thus the amount of energy required for a certain range. “Our engineers are constantly working on the miniaturization of mechanical and electronic components and combine this in the new and further development of aircraft with the improvement of aerodynamics and fuselage / wing construction,” says Karl Kaeser, CEO of Kasaero GmbH, describing the tasks of around 30 people . Kaeser is not only a sought-after expert in aircraft development and certification, but also a pioneer in electric flight who has already contributed to famous Solar Impulse flights, the design of the e-Genius and numerous modern e-models.

New fuel cell system makes more of “green” electricity in the air

A fuel cell reverses the manufacturing process of hydrogen, which together with oxygen turns it into electrical energy and water. One cell supplies a voltage of approx. 1 V. A row of these cells is put together to form a stack, which increases the total voltage to the desired level. Ancillary units supply the stack with hydrogen, air and cooling water and dissipate water vapor and electricity. The whole construct is called a “fuel cell system” or “fuel cell system”. The electricity is used to drive electric motors. The efficiency of the entire electric drive system – from hydrogen to the drive shaft – is around 60% today. Systems with internal combustion engines achieve at best 30%, gas turbines perhaps ten percent more. The new fuel cell system from PS-HyTech and Kasaero covers the entire energy and power requirement during cruise and is loaded very evenly. Additional battery packs are only used to provide the higher starting power. These are recharged by the fuel cell system during cruise. Should one of these energy storage systems actually fail, the remaining system enables a safe landing.

Positive ecological balance from generation to cross-country flight

The cost of producing hydrogen can be presented more transparently than that of fossil carriers such as natural gas and crude oil, which have to be extracted, transported and refined at great expense. Hydrogen can be produced almost anywhere in the world – industrially on a large scale, also in developing and emerging countries – or locally on a decentralized basis. For a positive ecological balance it is crucial that the electrolysis systems and also the means of transport are fed from regenerative sources.

Safety and ease of maintenance have top priority

Many buses, commercial vehicles and some cars such as the Toyota Mirai already run on hydrogen – there are no known major complications. When developing the new PS-HyTech / Kasaero system, safety and low maintenance are the top priorities.

Pure hydrogen itself does not burn or explode, is non-toxic and odorless. The spherical hydrogen tank is wound from a very high quality carbon fiber in a new process. Extremely low quality fluctuations and a particularly high load-bearing capacity of the fibers reduce the specific tank weight from 15 kg per kg of hydrogen to a ratio of 5: 1. “This is a real quantum leap,” says Stadthalter happily. The comparatively low mass is also noticeable in a hypothetical crash. The greatest hazard potential of hydrogen comes from the mechanically stored pressure energy in the 700 bar tank. If a tank with a volume of 250 l (this corresponds to 10 kg of hydrogen or 200 kWh of drive energy or 10 hours of flight time) actually bursts, this only corresponds to the explosive force of around half a liter of gasoline in an ignitable mixture. The safety concept for aircraft includes fast tank emptying in emergency situations, triggered independently by rescue systems. This makes the tank pressureless and safe in the event of a fall.

“Even with a leak in the hydrogen system, the risk remains manageable. If there is a small leak, the hydrogen disappears through all the cracks before it can collect anywhere and possibly form oxyhydrogen. In the event of a major leak, the outflow speed is so high that the hydrogen can hardly ignite. The penetration of air into the pressurized hydrogen system is also not technically possible, which is why no oxyhydrogen can form in this way, ”says Stadthalter.

The spherical tank is tested and certified according to the guidelines of the automotive industry. The required safety factor is 2.25: This means that for a tank with an operating pressure of 700 bar, the required burst pressure is 1,575 bar. In addition to many other tests, the tank has to endure 45,000 simulated refueling processes. It is then approved for 5,000 fillings, each of which allows around 7 hours of flight time or a range of around 1,000 kilometers. “With the PS-HyTech / Kasaero system, you can theoretically fly 5 million kilometers,” says Kaeser. “It remains to be seen whether this distance is actually covered with an ultralight or small aircraft.”

So far there are no licensing regulations for ultralight aircraft with fuel cell systems and therefore no maintenance plans. We will work intensively on this over the next two years. “From a technical point of view, our electro-hydrogen drive is almost maintenance-free,” says Stadthalter. “An annual inspection seems useful to us.”

Become part of an exciting (r) evolution – request information folder!